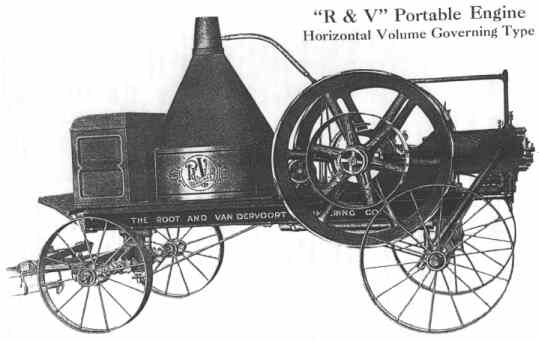

Volume Governed Engines

Built in 3, 5, 8, 10, 14, 18 and

25 hp sizes

|

|

|

| Volume Governing means regulating

the force of the impulse by controlling the amount of each charge.

This does not mean reducing or regulating the number of explosions

in the cylinder. Where power is wanted for work requiring close speed

regulation, constant or custom service, with maximum reliability,

the R&V Volume Governing Engines should be sold. This type is

unequaled for use in electric lighting plants, machine shops, creameries,

cotton gins, custom shelling, grinding or feed cutting. The

"R & V" Horizontal Engine, volume governing, is of

the four cycle type, especially designed to meet the requirements

of those wanting a strictly high-grade machine. We offer this engine

as an exceedingly reliable and durable motor for all power purposes.

It is now generally conceded that oil engines in small and medium

powers are more economical, convenient, and safer. They require

less attention, and in other respects are superior to steam power. |

|

|

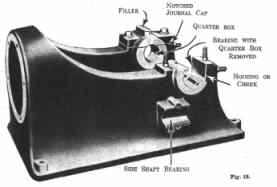

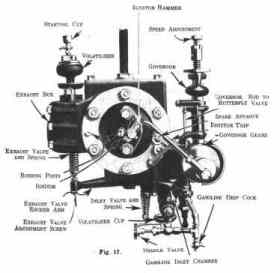

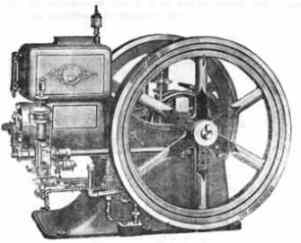

Bed: The bed

is of the center crank - box

type, with unusually heavy housings between cylinder and bearings.

There are no exposed ribs thus giving a very smooth outline. The top

surface of the housings are well above the center line of the engine,

thus insuring a very rigid frame. The massive proportions of this

bed are shown in the above illustration. |

Main Journals:

These journals are of the quarter box type, lined with genuine Babbitt,

penned, bored and hand-scraped to size.

The cheeks which receive the thrust are adjustable to compensate for

wear, and thus preserve original alignments. The journal caps are

notched over the frame, forming a rigid tie between housing and journal

support, as clearly shown. Under the journals are cored chambers,

which contain the lubricant for automatically oiling the main journals

by means of a chain oiler. |

|

| Igniter:

Of the two forms of ignition in present-day use, the jump spark and

make-and-break, we have adopted the make-and break system, as it possesses

numerous advantages over the jump spark. It requires no high-tension

current, hence is not liable to trouble from short circuits, requires

no finely adjusted coil, makes a larger, fatter spark and has proven

itself generally more reliable and free from trouble or break-downs

than the jump spark. The term "make-and-break" has been

applied to this system because when the igniter is tripped, the two

electrodes are first brought together inside of the cylinder and make

or close the electric circuit. Immediately following, these two points

are suddenly drawn apart, breaking the circuit and producing the spark,

it being an electrical fact that on closing a circuit there is no

spark and upon breaking it a spark is produced. Current is being used

only while the electrodes are in contact which is a very short space

of time. Hence the igniter is economical in current consumption. The

igniter is placed in the center of the cylinder head. All parts are

made from drop forgings except the trip, which is of tool steel. The

electrodes are of the hammer type, capped with special points that

are extremely durable, thus assuring a good, strong spark for over

a year's continuous use. The igniter trip is very simple, positive

in action, not f liable to get out of order, requires no r delicate

adjustment, and is practically noiseless. When desired, a device for

advancing the spark is furnished with these engines as an extra. |

| Volatilizer:

During exceptionally cold weather, gasolene will not readily

gasify, which under ordinary conditions causes more or less trouble

in getting engine to start. To overcome this, we now furnish a volatilizer

screwed to the exhaust box cap on all Horizontal Volume Governing

Engines of 5hp and larger. In addition we furnish a heater tray attached

underneath the inlet air pipe, thus making it possible to start all

sizes of engines under any conditions of weather and in all temperatures.

|

|

| Batteries:

We furnish each of our engines with the best and most approved

type of battery that the market affords, as so many engine failures

are traced to a poor quality battery. Fittings:

These are of the best quality we can buy. All small details of construction

receive the most exact and careful attention.

Accessories:

One set of Edison-Lalande batteries, consisting of five type"RR"

cells with spark coil and switch all substantially boxed, or a magneto.

Gasolene tank with pipe and fittings. Muffler, exhaust pipe. Oil

can. One monkey wrench and two connecting-rod wrenches. Also an

instruction book for setting up. starting and taking care of engine. |

| Edison Spark Coil

In order to obtain a bright, hot

spark, which will unfailingly ignite the explosive mixtures in the

combustion chamber, a good spark coil must be used in connection

with a battery. |

|

|

|

Type "RR" Cell: For stationary

engines. Large gas engine model. Capacity 300 ampere-hours. We recommend

five of these cells for stationary engines, as it develops a strong,

constant current continuously, no attention being necessary until

the entire charge is exhausted. They do not waste while idle, are

simple in construction. Complete Cell with porcelain jar, $5.80.

| Price

of renewal parts

1 Zinc plate (capacity,

1 charge) $1.00 1 Copper Oxide plate (1 charge) $1.10

1 Can Caustic Soda (1 charge) $0.56c 1 Bottle heavy paraffin

oil (1 charge) .56c

Total ----------------------------$2.80 |

|

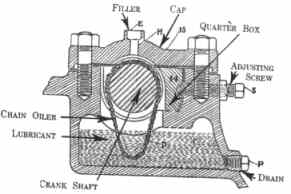

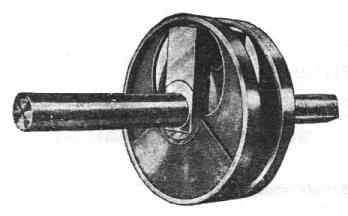

|  Crankshaft. Crankshaft.

The crankshaft is turned from a

solid steel forging and counter-balanced with weighted discs securely

bolted to the webs of the crank, thus counter-weighting the crank

and reciprocating parts at the crank rather than in the rim of the

balance wheel, as is common gas engine practice. We consider this

system of counter-weighting the most correct method as it brings

the strains directly on the crank rather than through the shaft,

and in high speed work assures a much smoother running engine. The

construction of the crank shaft is clearly shown in the illustration. |

|

|

|

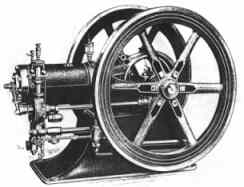

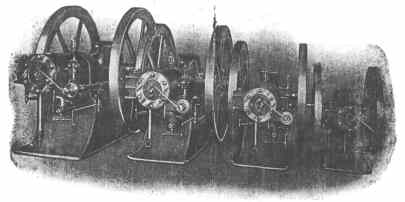

A group of Horizontal Volume

Governed Engines. |

|

|

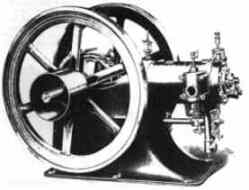

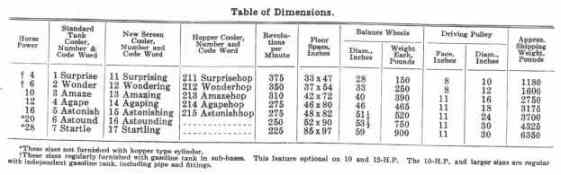

| This is a later version of the Volume Governing

Engine using a detachable water hopper.. It came in hopper or tank

cooled. While this style of engine is

higher in price than the Triumph and similar engines, the volume

governing engines is practically in a class by itself and possesses

a distinct individuality because few manufacturers of engines make

anything of the kind. |

|

|

|

As found

As found |

|

The finished job

The finished job

This particular engine, above, uses

a high tension magneto (Bosch) and spark plug, possibly used on

export models for better reliability away from the ready availability

of factory spare parts. The USA version, from factory photographs,

show low tension ignitor and battery setup, although a magneto is

mentioned. Batteries of the day, made with glass cases, would have

been fragile to transport overseas.

R&V tag with name of agent

in Argentina.

R&V tag with name of agent

in Argentina.

The 3 photos above and the tag

are from a 3hp Volume Governed R&V engine from Argentina. #08885

Any communication to owners of R&V engines can be made through

Site Custodian.

Official R&V Web Site © 2000 - 2023

|

|